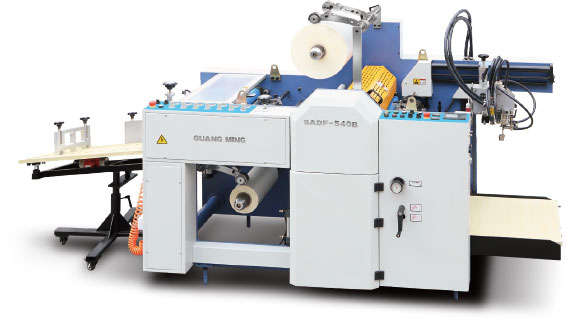

Automatic Doubel Side Laminating Machine ∨

-

SADF-540B

Automatic Doubel Side Laminating Machine

- To suit both single side and double

side lamination

Model SADF540B is one of our fully automatic double side laminators newly developed upon market needs. It is a processing technology which targets in laminating small size paper with pre-glued film after heated、pressured finally realize the paper and film laminated together .The most attractive features of the machine are compact structure and humanized design. SCHNEIDER, OMRON etc international brands of electrical and photovoltaic parts equipped perfect the running stability and safety of the laminator. The machine realizes automated operation, and suits pre-glued film single side and double side paper lamination.